Que signifie votre code Code Défaut MERCEDES ?

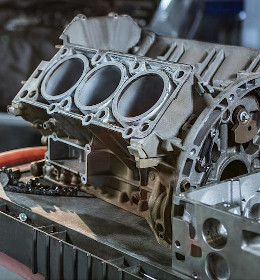

Grace au système OBD, les

Mercedes

fabriqués après 1996 sont normalement équipés d'une prise diagnostique OBD.

Si l'ordinateur de la voiture rencontre un problème,un code d'erreur ou un code de diagnostic (DTC)

sera stocké dans la mémoire de l'ECU de la voiture.

Avec un lecteur OBD branché sur le port OBD (On-Board Diagnostics) de la voiture, vous pouvez lire la liste des codes stockés, et donc découvrir quel est le problème.

Les codes suivent une formule permettant de savoir généralement quel est le problème avant même de regarder le tableau ci-dessous.

Nous vous présentons ci-dessus une liste très complète des différents codes défauts possibles.

Si le code défaut de votre auto s'affiche au tableau de bord, vous n'aurez peut-être même pas besoin d'un lecteur OBD . il sera dans la liste .

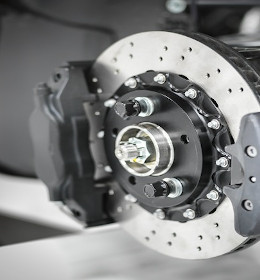

Réparer le code défaut de votre auto, c'est potentiellement simple à faire avec vos revues et méthodes techniques.

Réparer le code défaut de votre auto, c’est potentiellement simple à faire avec nos revues et méthodes techniques

| Code | Libellé |

|---|---|

| P1482-008 | Glow output stage-Cable has Short circuit to ground. |

| P1482-032 | Glow output stage-Incorrect diagnosis sequence. |

| P1482-064 | Glow output stage-Implausible reception byte. |

| P1520-016 | Cruise control- Control contact alone. |

| P1520-032 | Cruise control- No check contact. |

| P1520-064 | Cruise control- Operating parts signals through CAN are implausible. |

| P1520-128 | Cruise control- Operating unit has contact short (two contacts synchronous). |

| P1612-001 | Voltage terminal 15- Analysis circuit is faulty |

| P1613-001 | Control unit CDI- Lower stabilization limit. |

| P1613-002 | Control unit CDI- Upper stabilization limit. |

| P1614-001 | Control unit CDI- Recovery error. |

| P1614-016 | Control unit CDI- Shut-off monitoring. |

| P1614-032 | Control unit CDI- Quantity stop. |

| P1614-064 | Control unit CDI- COMMUNICATION1. |

| P1614-128 | Control unit CDI- COMMUNICATION2 |

| P1615-001 | Control unit CDI- The voltage supply is too low |

| P1615-002 | Control unit CDI- The voltage supply is too high |

| P1617-001 | Control unit CDI- An error occurred during the last write operation |

| P1617-002 | Control unit CDI- Adaptation values of EEPROM. |

| P1617-016 | Control unit CDI- EEPROMCOMMUNICATION. |

| P1617-032 | Control unit CDI- CAN bus open circuit during variant coding. |

| P1617-064 | Control unit CDI- No harmonizing version number. |

| P1617-128 | Control unit CDI- Codeword is incorrect or missing. |

| P1630-016 | Immobilizer- Control unit WSP immobilizer does not answer. |

| P1630-032 | Immobilizer- Incorrect authentication value. |

| P1630-064 | Immobilizer- EEPROM test in common rail control module indicates a fault. |

| P1663-001 | Rail pressure control valve- The signal voltage is too low. |

| P1663-002 | Rail pressure control valve- The signal voltage is too high. |

| P1698-004 | AC compressor shutoff-Cable has Short circuit to positive or Short circuit to ground |

| P1698-008 | AC compressor shutoff-Cable has Open circuit |

| P1698-128 | AC compressor shutoff-CAN data transfer |

| P1699-001 | Engine start/stop- Engine stop is unsuccessful |

| P1699-002 | Engine start/stop- Engine start is unsuccessful |

| P1699-008 | Engine start/stop- Plausibility1 |

| P1699-016 | Engine start/stop- Plausibility2 |

| P1699-032 | Engine start/stop- Plausibility3. |

| P1699-064 | Engine start/stop- Plausibility clutch UP. |

| P1699-128 | Engine start/stop- Plausibility clutch DOWN. |

| P1747-062 | Fault from instrument cluster over CAN. |

| P1999-064 | Engine oil sensor-Oil quality. |

| P1999-065 | Engine oil sensor-Water in engine oil |

| P1999-074 | Misfiring of cylinder 7. |

| P1999-075 | Misfiring of cylinder 8. |

| P1999-076 | Misfiring of cylinder 9. |

| P1999-077 | Misfiring of cylinder 10. |

| P1999-078 | Misfiring of cylinder 11. |

| P1999-079 | Misfiring of cylinder 12. |

| P1999-087 | Misfiring of cylinder 7, damages TWC. |

| P1999-088 | Misfiring of cylinder 8, damages TWC. |

| P1999-089 | Misfiring of cylinder 9, damages TWC. |

| P1999-090 | Misfiring of cylinder 10, damages TWC. |

| P1999-091 | Misfiring of cylinder 11, damages TWC. |

| P1999-092 | Misfiring of cylinder 12, damages TWC. |

| P2C8C | DC/DC converter temperature sensor 4 circuit/open |

| P2C8D | DC/DC converter temperature sensor 4 circuit range/performance |

| P2C8E | DC/DC converter temperature sensor 4 circuit low |

| P2C8F | DC/DC converter temperature sensor 4 circuit high |

| P2CA5 | DC/DC converter temperature sensor 5 circuit/open |

| P2CA6 | DC/DC converter temperature sensor 5 circuit low |

| P2CA7 | DC/DC converter temperature sensor 5 circuit high |

| P2CA8 | DC/DC converter temperature sensor 5 circuit range/performance |

| P2CA9 | DC/DC converter temperature sensor 6 circuit/open |

| P2CAA | DC/DC converter temperature sensor 6 circuit low |

| P2CAB | DC/DC converter temperature sensor 6 circuit high |

| P2CAC | DC/DC converter temperature sensor 6 circuit range/performance |

| P2D2B | High-voltage battery pack coolant temperature sensors 1 and 2, correlation |

| P2D34 | High-voltage battery inductive charger control circuit range/performance |

| P2D35 | High-voltage battery inductive charging system high voltage interlock circuit performance |

| P2D36 | High-voltage battery inductive charger output voltage performance |

| P2D37 | High-voltage battery inductive charger input circuit range/performance |

| P2D52 | High-voltage battery pack coolant temperature sensor 3 circuit/open |

| P2D53 | High-voltage battery pack coolant temperature sensor 3 circuit range/performance |

| P2D54 | High-voltage battery pack coolant temperature sensor 3 circuit low |

| P2D55 | High-voltage battery pack coolant temperature sensor 3 circuit high |

| P2D56 | High-voltage battery pack coolant temperature sensor 3 circuit intermittent/erratic |

| P2D83 | Battery charger 2 input current sensor circuit low |

| P2D84 | Battery charger 2 input current sensor circuit high |

| P2D85 | Battery charger 2 input current sensor circuit range/performance |

| P2DAC | Electric drive motor 1 temperature sensor 2 circuit/open |

| P2DAD | Electric drive motor 1 temperature sensor 2 circuit range/performance |

| P2DAE | Electric drive motor 1 temperature sensor 2 circuit low |

| P2DAF | Electric drive motor 1 temperature sensor 2 circuit high |

| P2DB0 | Electric drive motor 1 temperature sensor 2 circuit intermittent |

| P2DB1 | Electric drive motor 1 temperature sensor 3 circuit/open |

| P2DB2 | Electric drive motor 1 temperature sensor 3 circuit range/performance |

| P2DB3 | Electric drive motor 1 temperature sensor 3 circuit low |

| P2DB4 | Electric drive motor 1 temperature sensor 3 circuit high |

| P2DB5 | Electric drive motor 1 temperature sensor 3 circuit intermittent |

| P2DB6 | Battery charger 2 cooling system performance |

| P2DB7 | Battery charging system 2 high voltage interlock circuit/open |

| P2DB8 | Battery charging system 2 high voltage interlock circuit performance |

| P2DB9 | Battery charging system 2 high voltage interlock circuit low |

| P2DBA | Battery charging system 2 high voltage interlock circuit high |

| P2DBB | Battery charging system 2 high voltage interlock circuit intermittent/erratic |

| P2DBC | Battery charger 2 coupler lock position sensor circuit/open |

| P2DBD | Battery charger 2 coupler lock position sensor circuit range/performance |

| P2DBE | Battery charger 2 coupler lock position sensor circuit low |

| P2DBF | Battery charger 2 coupler lock position sensor circuit high |

| P2DC0 | Battery charger 2 coupler lock position sensor circuit intermittent/erratic |

| P2E2C | Battery charger 1 module supply voltage performance |

DEFINISSEZ VOTRE MARQUE POUR ACCEDER A VOS CODES DEFAUTS

-

Revue technique RTA

Revue Technique Automobile

La revue technique de référence depuis 1946. La RTA est une revue papier pour tous publics, qui vous permet d'effectuer les petites et les grosses réparations

Voir le descriptif

Voir le descriptif

-

Entretien courant MTA

Méthode Technique Automobile

La MTA est issue de nos outils destinés aux pros de l'auto. Ces méthodes en ligne permettent d'effectuer les opérations de maintenances de votre auto (filtres, courroies, etc.)

Voir le descriptif

Voir le descriptif

-

Toutes réparations MTAx

Méthode Technique Automobile Expert

La MTA expert est un outil en ligne destiné aux experts en mécanique et en carrosserie, pour effectuer tous types de réparations sur une voiture.

Voir le descriptif

Voir le descriptif